Distinguishing clean from contaminated sea moss is essential for businesses looking to minimize risks when importing sea moss as a raw material for pharmaceutical, cosmetic, or food processing. However, understanding how to differentiate between clean and contaminated sea moss is not always straightforward. If you are seeking to gain deeper insights into how to clean sea moss properly, the following guide will provide you with essential knowledge and direction in choosing a trustworthy supplier to ensure the stability of your production inputs.

1. Why is it critical to distinguish clean from contaminated sea moss?

In today’s global market, where food, cosmetic, and pharmaceutical industries face increasingly stringent safety regulations, distinguishing clean from contaminated sea moss is no longer optional but a mandatory requirement for bulk buyers.

Clean sea moss is defined as raw material that contains no more than 12% moisture, free from sand, heavy metals, and harmful microorganisms, and has been dried and processed in a hygienic environment. In contrast, contaminated sea moss carries significant risks: it may contain dirt, microbial contamination, residual sea salts, or even industrial pollutants if harvested from polluted waters.

Failing to manage raw material quality at the sourcing stage can lead to serious consequences: shipment rejections, brand damage, and violations of international safety standards. Particularly in industries like food, cosmetics, and pharmaceuticals, even a single substandard batch can cause hundreds of thousands of dollars in losses, disrupt production timelines, or compromise product safety due to lapses in quality control.

Therefore, distinguishing clean from contaminated sea moss is not just a matter of technical compliance, it is a strategic imperative. It protects the integrity of your supply chain, ensures regulatory compliance, and safeguards long-term production reliability for any business operating in international trade.

Lam Hong sea moss products

2. Common contaminants in sea moss: Clean and contaminated sea moss

Understanding the common types of impurities found in contaminated sea moss is essential for designing an effective screening and quality assurance protocol during procurement and processing. Distinguishing clean and contaminated sea moss requires both technical insight and practical assessment.

Frequently identified contaminants:

- Sand and silt: Often embedded in the sea moss strands; if not properly washed, they may remain in the final product.

- Shell fragments, stones, and marine debris: Typically introduced when sea moss is dried directly on sandy beaches or unsanitary ground surfaces.

- Microorganisms (mold and pathogenic bacteria): Can develop if the sea moss is overexposed to humidity, dried improperly, or stored under substandard conditions.

- Heavy metals: Such as lead, arsenic, and mercury, commonly present in sea moss harvested from polluted coastal areas.

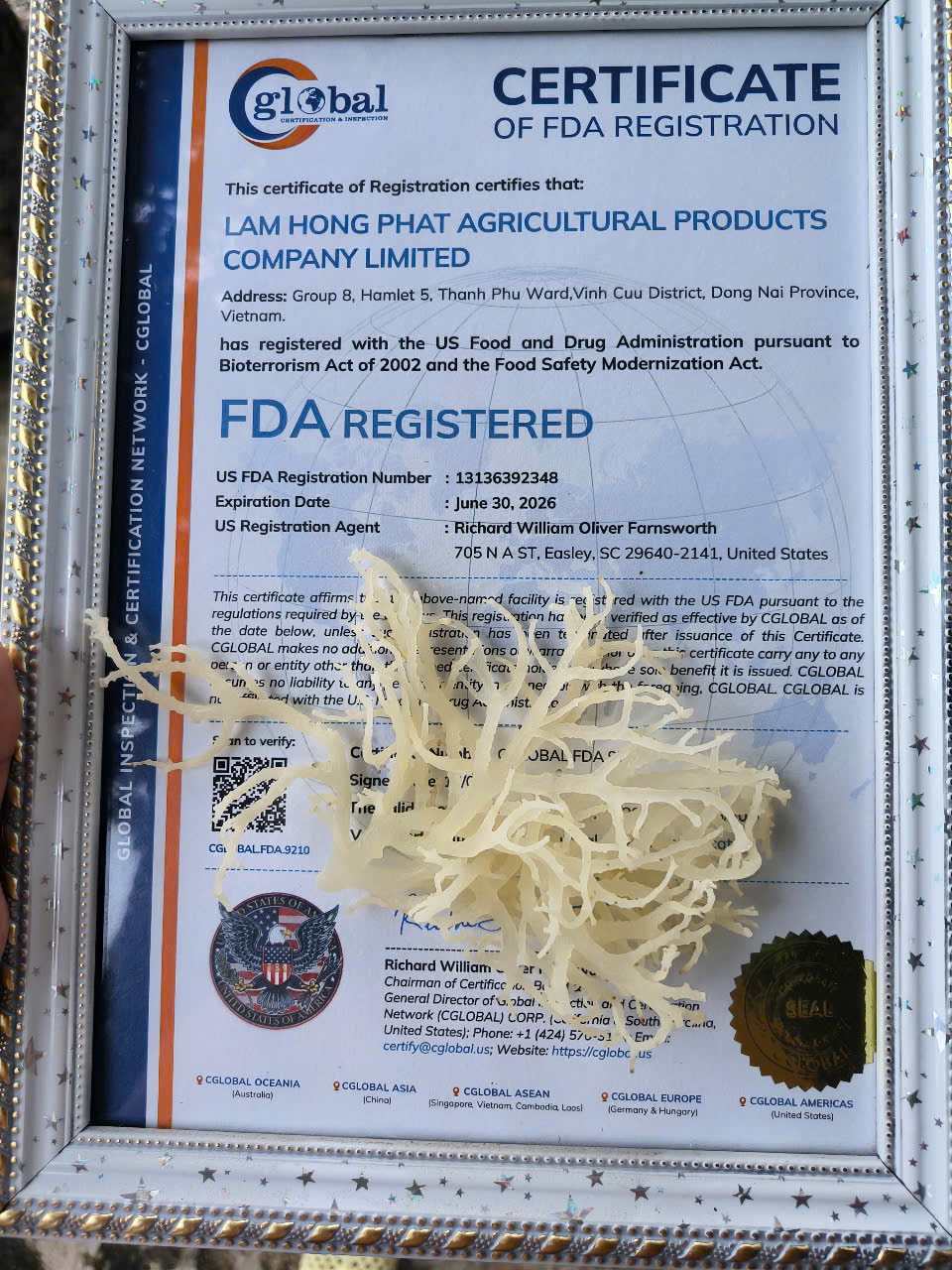

Certifications of Lam Hong sea moss products

For bulk importers and exporters, it is imperative to ensure that only clean sea moss is used in processing. This must be verified through certifications such as COA (Certificate of Analysis), HACCP, ISO, and independent laboratory reports.

Properly distinguishing clean from contaminated sea moss should not rely solely on visual inspection. Modern suppliers increasingly use digital testing systems and on-site analytical devices to assess microbial safety, moisture content, and contamination levels, critical for quality control across the entire supply chain.

In addition to certifications, buyers should assess the supplier’s real-world capacity and sourcing conditions. A strong supplier does not just meet international documentation standards but also maintains a clean, traceable harvesting environment from the outset. Evaluating the origin of the raw material is a vital first step, while certifications serve as the final proof of product quality and supplier reliability.

By understanding these aspects, buyers can better evaluate how to clean sea moss properly and ensure that sourcing decisions support consistent quality and regulatory compliance.

3. A practical guide on how to clean sea moss properly: Methods, pros, and cons

Understanding how to clean sea moss properly is a crucial step to ensure consistent quality when using sea moss as a raw material in food, cosmetic, or pharmaceutical production. Proper cleaning helps manufacturers avoid the risks associated with contaminated sea moss and uphold international safety standards.

Images of clean Lam Hong sea moss immediately after harvest

Standard cleaning procedure:

- Initial rinse in clean water to soften the sea moss and remove surface-level dust and sand.

- Manual cleaning to remove visible impurities such as debris, fine sand, foreign seaweed, and marine waste.

- Secondary soaking in fresh water for 8–12 hours to fully hydrate the sea moss, making it translucent and soft.

- Light disinfection using diluted apple cider vinegar or lemon juice to eliminate harmful microorganisms.

- Drying naturally under sunlight for 2–3 days or via mechanical drying, ensuring final moisture content is below 12%.

- Vacuum packaging to prevent recontamination and extend shelf life.

|

Method |

Advantages |

Disadvantages |

Best for |

|

Manual Cleaning |

Preserves natural fiber structure; high precision |

Labor-intensive and time-consuming |

Premium small-batch products |

|

Water Agitation Machines |

Deep cleaning; effective for removing fine particles |

May damage delicate sea moss strands |

Large-scale food or pharmaceutical batches |

|

Chemical Disinfection |

Highly effective against fungi and bacteria; meets strict standards |

Potential nutrient loss if overused |

Cosmetics and food for highly regulated markets |

Knowing how to clean sea moss properly not only optimizes the production process but also enhances your credibility when working with international buyers. Proper cleaning is a key part of broader quality control strategy in distinguishing clean from contaminated sea moss, ensuring your products meet regulatory and market expectations.

Close-up of Lam Hong sea moss products

4. What are the best industrial cleaning standards for sea moss?

Choosing the correct cleaning method can determine whether a shipment is rejected or meets export-grade standards. For businesses in the raw materials sector, distinguishing clean from contaminated sea moss is not just a quality control task—it's a risk mitigation strategy and a path to higher product value.

Comparison of three main cleaning methods:

|

Method |

Primary Application |

Production Advantage |

|

Premium Manual Cleaning |

High-end cosmetics, organic handmade gels |

Supports brand-building, preserves the sea moss fibers |

|

Industrial-Scale Machinery |

Pharmaceuticals, beverages, industrial jellies |

Ensures consistency, high output |

|

Light Acid Sterilization |

Pharmaceutical and cosmetic exports to EU/USA |

High microbial elimination, meets strict testing |

The modern trend favors a hybrid approach that combines these methods to both preserve the natural quality of sea moss and meet stringent international inspection requirements.

Raw material suppliers like Lam Hong sea moss have adopted a three-step cleaning process: coarse filtration → pure water treatment → mild disinfection. This approach retains essential mineral content without affecting the color or natural aroma of the product. It has been highly rated by importers in Germany, Japan, and South Korea, especially for bulk orders.

In short, when it comes to distinguishing clean from contaminated sea moss, following a standardized, multi-step cleaning protocol is crucial to gaining the trust of global buyers and maintaining consistent export quality.

We hope the information on distinguishing clean from contaminated sea moss has provided you with valuable insights into the product. If you are currently looking for a reliable sea moss supplier in Vietnam, especially in the Nha Trang region, don’t hesitate to contact Lam Hong sea moss, a trusted partner you shouldn’t overlook.