Sourcing the best sea moss for industrial processing plays a crucial role in supporting sustainable business growth and enhancing competitiveness in the global market, especially for companies targeting high-demand markets such as the U.S., Europe, South Korea, and Japan. Take a moment to explore the content below for more valuable insights.

1. What is the best sea moss for industrial processing? Standards and comparative analysis

When identifying the best sea moss for industrial processing, manufacturers must evaluate key technical indicators: moisture content ≤12%, carrageenan concentration ≥18%, impurity level ≤3%, and consistent gel-forming ability in both food and industrial applications. Among the major sea moss types available for large-scale processing, Gracilaria, Eucheuma cottonii, and Eucheuma spinosum are the most commonly sourced.

According to data from The Moss Way, Gracilaria is the most affordable variety but contains lower levels of minerals, making it more suitable for household gel products rather than scalable industrial applications. In contrast, Eucheuma cottonii and Eucheuma spinosum contain significantly higher levels of carrageenan, making them ideal for high-yield processing lines that demand consistent gelling properties and a strong polysaccharide profile.

Images of workers harvesting sea moss at Lam Hong sea moss is farm

These two types Cottonii and Spinosum, collectively contribute 75-83% of global Eucheuma trade value in the hydrocolloid industry, according to the FAO and Lam Hong sea moss. The carrageenan market, in which they are central, is currently valued at USD 967 million (2024) and is projected to reach USD 1.607 billion by 2033, with a CAGR of 5.8%, largely driven by demand from food and industrial sectors (Straits Research).

Between the two, Eucheuma cottonii is known for producing rigid kappa-type gel, suitable for frozen foods and stabilizers. Meanwhile, Eucheuma spinosum forms a softer gel, ideal for cosmetic gels and soft gelatin-based dairy substitutes. Therefore, the optimal choice depends on the specific industrial application, whether frozen food production, biodegradable packaging, or hydrocolloid extraction

In summary, the best sea moss for industrial processing is typically high-carrageenan eucheuma types such as cottonii or spinosum, selected for their superior supply volume, carrageenan concentration, and industrial handling capabilities.

Notably, both Eucheuma cottonii and Spinosum are cultivated extensively along Vietnam’s coastline, especially around Nha Trang. Products harvested from this region consistently meet the stringent demands of food, beauty, and cosmetic industries, making Vietnam a strategic source of sea moss for food and industrial applications.

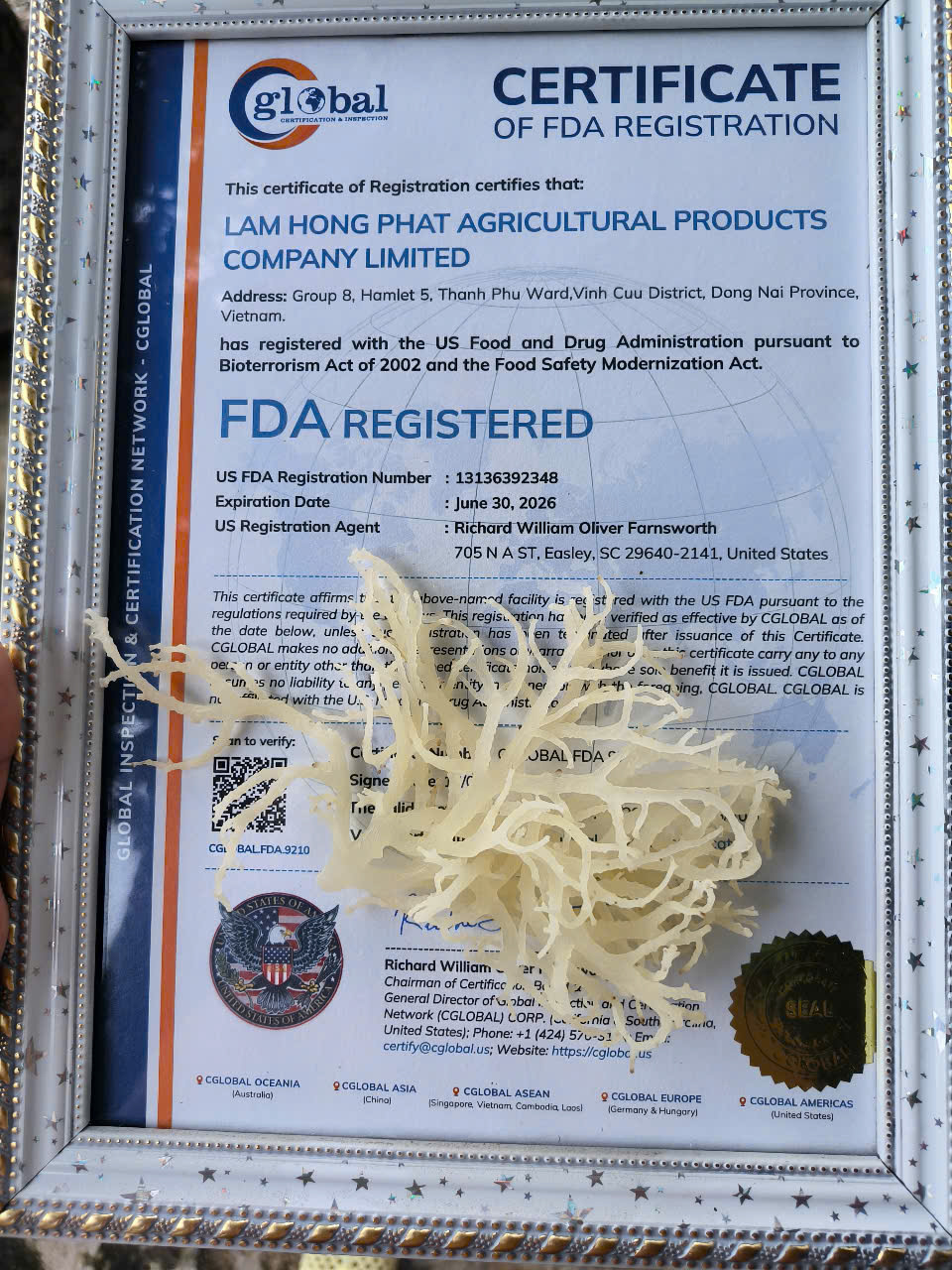

Quality certifications for Lam Hong sea moss products

2. Sea moss for food and industrial applications: An irreplaceable role

In both the food and industrial manufacturing sectors, sea moss for food and industrial applications plays a critical role as a natural stabilizer, gelling agent, texture enhancer, and viscosity modifier. This segment accounted for 38.7% of global carrageenan revenue in 2022, according to market research from Grand View Research.

The global sea moss market was valued at USD 2.58 billion in 2023, with projections reaching USD 2.99 billion by 2030, reflecting a compound annual growth rate (CAGR) of approximately 2.1% (Grand View Research). Notably, 56.1% of the revenue comes from raw sea moss products, with primary use in food and beverage applications, underscoring the indispensable position of sea moss in the global food industry.

Currently, sea moss-derived natural carrageenan is widely used as a gelatin alternative in vegan products such as plant-based milk, fortified sea moss beverages, puddings, sauces, and frozen teas. As the clean label trend accelerates, consumers are increasingly favoring natural ingredients over synthetic additives like xanthan gum. In this context, sea moss for food and industrial applications enables manufacturers to meet consumer demand for transparency, food safety, and environmental responsibility, while elevating brand credibility.

Lam Hong sea moss products in the Vietnamese market

To meet stringent import regulations in markets such as the EU and the U.S., manufacturers must source from sea moss suppliers with food-grade or pharmaceutical-grade certifications, such as HACCP and ISO 22000. A stable and transparent supply chain not only ensures regulatory compliance but also reduces traceability risks and mitigates shipment rejections due to excessive impurities or heavy metal residues.

3. What is the best sea moss for industrial processing when targeting sea moss importers for the food industry?

When addressing the question, “what is the best sea moss for industrial processing”, particularly for sea moss importers for the food industry, one must understand the strict quality expectations of major markets such as the United States, Germany, and Turkey. These three countries collectively accounted for 61% of global sea moss imports between March 2023 and February 2024, according to data from Volza and Grand View Research.

Buyers typically demand high levels of certification, including:

- Certificate of Analysis (COA) detailing moisture, impurity levels, and microbiological safety

- HACCP certification

- Full traceability down to the specific farming region or marine harvest location

In this landscape, the best sea moss for industrial processing must not only comply with food safety standards such as E407a (EU food-grade carrageenan), but also maintain continuous supply capacity, scalability, and verified quality assurance. Eucheuma cottonii and Eucheuma spinosum remain the top choices due to their high carrageenan content and extensive cultivation in Southeast Asia. Together, Indonesia and the Philippines supply 75–83% of global eucheuma exports, making them critical origins for global sea moss for food and industrial applications.

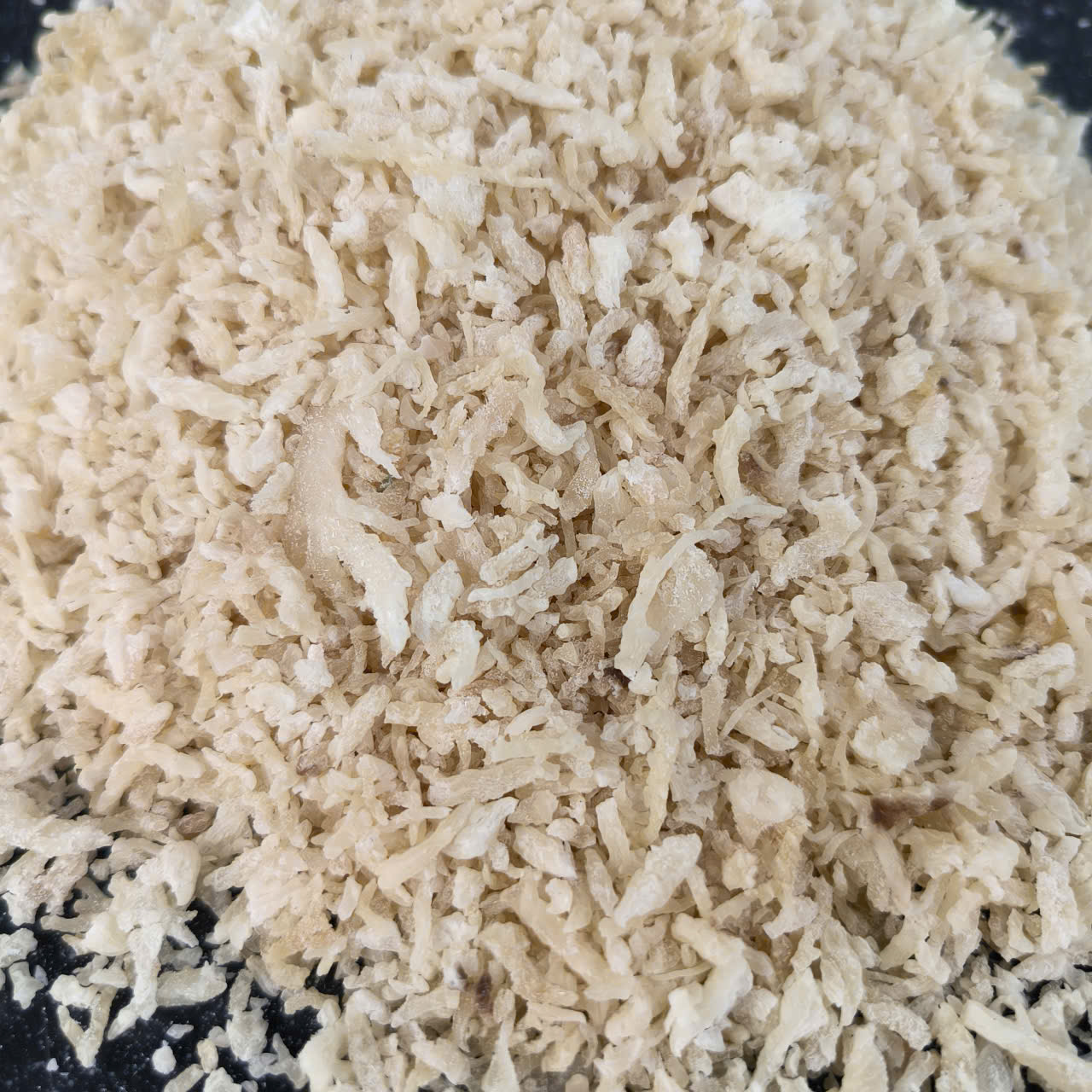

Products ready to be packaged for export at Lam Hong Sea Moss

Vietnamese exporters have also gained significant traction, accounting for 32% of global sea moss export shipments during the same period (Volza.com). This demonstrates Vietnam’s capability in volume handling, compliance with international standards compliance, and expertise in handling complex export logistics, such as vacuum-sealed containers and FOB shipping terms.

Although Lam Hong sea moss is not yet among Vietnam’s top sea moss exporters, we are confident in our ability to provide high-quality products that meet stringent buyer requirements while offering competitive input costs.

Therefore, when sourcing the best sea moss for industrial processing to serve sea moss importers for the food industry, industrial buyers should prioritize eucheuma sea moss, particularly cottonii or spinosum, sourced from Southeast Asia and validated through verifiable certification and traceability systems.

4. Strategic considerations when selecting the best sea moss supply for industrial processing

Selecting the best sea moss for industrial processing goes beyond meeting technical specifications, it requires a long-term strategic approach to supply chain management. Manufacturers must prioritize sea moss suppliers capable of fulfilling long-term contracts with consistent scalability and sustainability. For example, Indonesia produces approximately 9.96 million metric tons of marine algae annually, while Vietnam is targeting 500,000 metric tons per year by 2030.

Key criteria to consider include:

- Scalability: The ability to supply ≥100 metric tons per month, ensuring consistency and avoiding seasonal shortages.

- Certifications & traceability: HACCP, ISO, Organic, COA, and full traceability to the cultivation region.

- Processing technology: Semi-refined carrageenan accounts for more than 50% of total industry revenue, making it a key indicator of supplier capability.

- Modern logistics: Cold-chain container packaging and GDP-compliant shipping practices to reduce moisture loss and microbial risks.

Current market trends also reflect a shift in procurement models. Increasingly, manufacturers are selecting suppliers who offer not just raw sea moss, but integrated services such as co-manufacturing, sustainable aquaculture, and environmental certifications like MSC/ASC. These practices help reduce carbon footprints and justify premium product pricing.

Food, pharmaceutical, and cosmetics manufacturers are now seeking the best sea moss for industrial processing not only to ensure product consistency and regulatory compliance but also to align with green branding and cost-efficiency objectives.

Naturally, such stringent demands often push buyers toward large-scale exporters, where negotiating favorable pricing becomes difficult. If your business is seeking the best sea moss for industrial processing at a competitive cost, consider reaching out to Lam Hong sea moss as an alternative sourcing partner for flexible and strategic collaboration.